Control valves are an essential part of any piping unit. The basic function of these valves is to manage the flow of medium through different piping areas of a system. Ball and plug valves are two types of control valves that have similar functions and are often used interchangeably. However, they are still different in terms of their structure and overall function.

There are so many types of control valves to choose for your needs is a daunting task. Installing an inappropriate valve in your system can make it less efficient and even dangerous if you’re dealing with critical applications. This blog will help you understand the difference between plug and ball valves so you can make an educated decision on which one is right for your application. Read on to find out more.

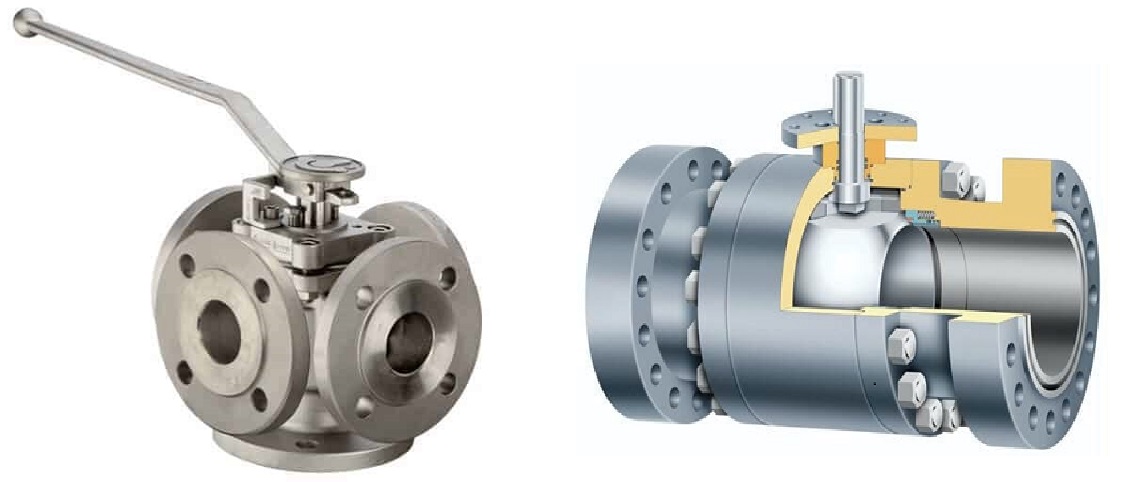

Related Products

What are Ball and Plug Valves?

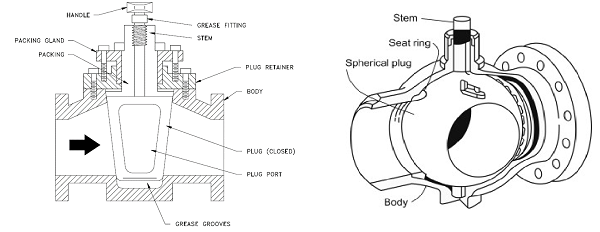

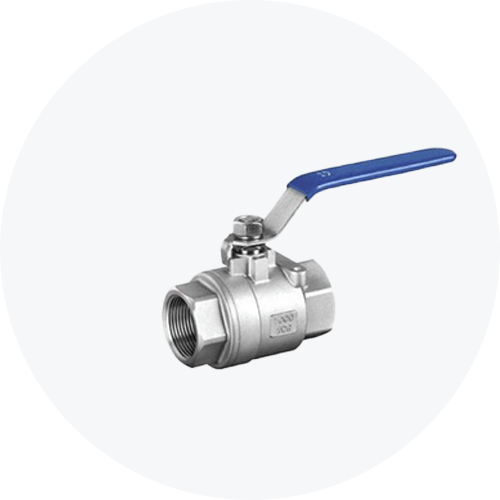

Let’s start with the basic definition of both ball and plug valves. Ball valves are a type of control valve that features a spherical disc inside. This disc has a hole in it that is called a port. When the port is in line with both ends of the valve, the valve is open and allows medium to flow through it easily. When the port is perpendicular to the ends of the valve, the valve is closed and the flow of medium stops.

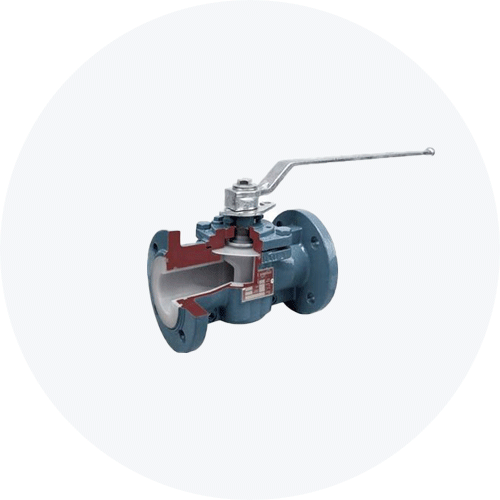

A plug valve is named so because it features a conically-tapered or cylindrical disc that resembles a plug. The plug features one or more passages going sideways through the plug that allow the fluid to pass through them. When the bored passage is in line with the flow, the valve is open and the fluid can flow through it freely. When the plug is turned, the solid part of the plug blocks the flow, hence closing the valve.

Source: https://blog.projectmaterials.com

Both ball and plug valves are quarter-turn valves, this means that a quick 90-degree turn of the actuator can help open or close the valves. They are quick-operation valves that are used for sealing and shut-off operations. Neither ball nor plug valves are suitable for throttling purposes. You can modify the design and structure of either valve to make it suitable for throttling but that would require very expensive customization.

What are the Differences Between Ball Valves and Plug Valves?

Ball and plug valves are very similar in terms of their basic function and application. Both are control valves that are used to provide tight shut-offs in different kinds of piping units. They also work on the same basic principle whereby a perforated disc is used to start or stop the flow of the medium. However, they have quite a few differences as well. Here is a look at some of the differences between ball valves and plug valves:

Construction

Both ball and plug valves feature bored discs in the center of the valve. A ball valve has a spherical disc with a hollow center. A plug valve has a conical or cylindrical disc with bored passages going through it. The disc or ball in a ball valve is smaller in size than the disc or plug in a plug valve. This is the reason why a plug valve is able to provide a tighter shut-off than a ball valve. Plug valves are also smaller in size as opposed to a ball valve. Their smaller footprint means plug valves can be installed in smaller units easily.

Source: https://www.sciencedirect.com https://hardhatengineer.com

Function

Ball and plug valves are control valves that are used to start and stop the flow of the medium. The sealing surface of the plug valve is much larger than that of a ball valve. The cylindrical or conical plug in the valve has a larger surface area so it can provide a better seal. However, a larger surface area also translates to greater torque. The high torque makes the valve inflexible and difficult to operate.

Source: https://www.sciencedirect.com http://www.wermac.org

Ball valves, on the other hand, provide torque-free operation. The smaller surface area can lead to low sealing performance but new advancements in chemical sealants and seal injections mean ball valves can easily overcome this problem. Ball valves are less heavy than plug valves. Since plug valves feature a solid disc or plug in the center that is larger in size, it is heavier as well. This is the reason why plug valves are usually used in smaller applications as large-sized plug valves are expensive to make and can get really heavy.

Maintenance

Control valves need regular maintenance to keep working effectively. Ball valves are difficult to maintain as the ball or disc is located deep inside the valve and cannot be easily accessed. In fact, one of the main criticisms of ball valves is that over time, the body cavity of the valve accumulates particles from the medium that is then difficult to remove.

Source: https://blog.projectmaterials.com

Plug valves are easier to maintain as the plug can be easily removed and cleaned. This also gives easy access to the rest of the valve body so it can be maintained without much hassle. Plug valves have a simpler construction, they don’t have a lot of moving parts. They are also smaller in size than most regular valves. This makes it easier to repair and maintain.

Types

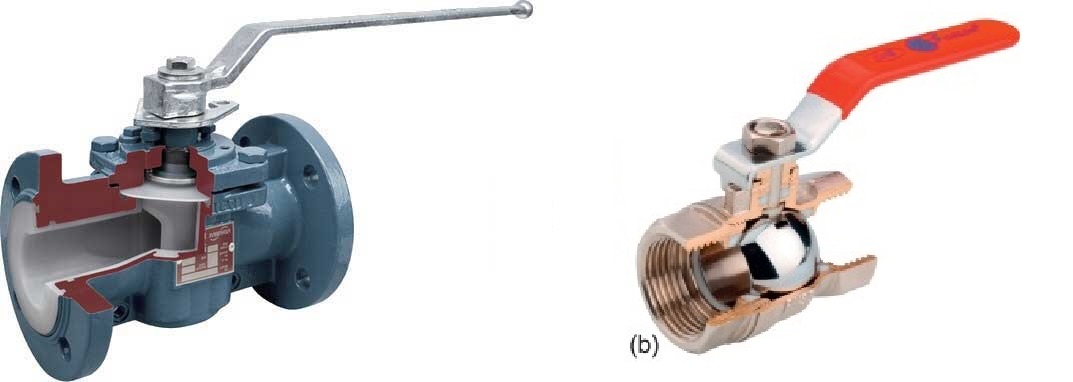

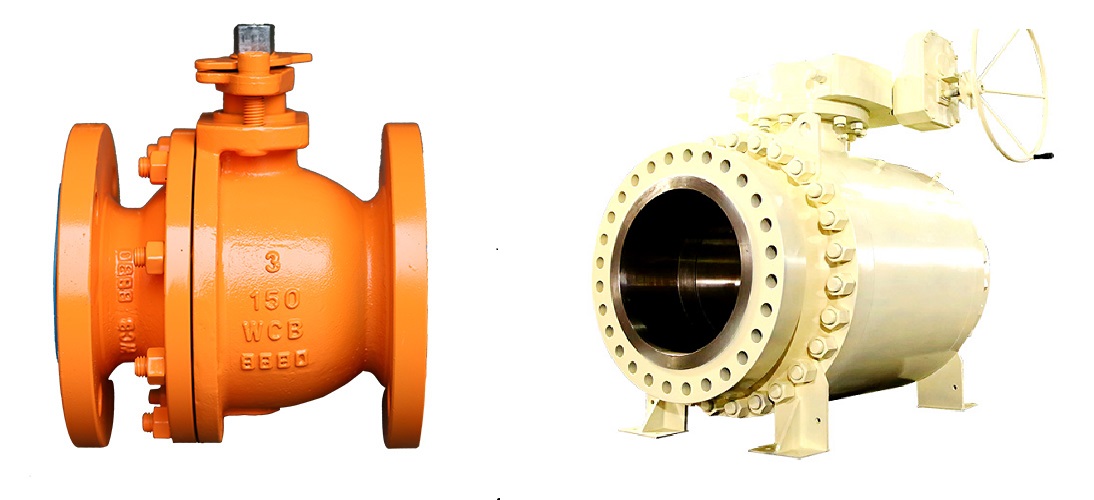

Ball valves are extremely versatile control valves. They have a number of different types based on their structure and function, ball valve flange type and metal seat ball valve are one of which. This is the reason why they are one of the most popular valves used in the piping industry today. You can find full and reduced bore ball valves. Full bore ball valves allow unobstructed flow of medium through the valve. Reduced bore or reduced port valves restrict the flow of medium as the size of the bore is less than the diameter of the pipeline.

Ball valves can also be floating or trunnion mounted. Floating ball valves are used in applications where a bi-directional shut-off is required. Trunnion mounted ball valves are used in high-pressure, high-temperature operations. The working principle of trunnion mounted ball valve is also different from floating ball valves.

Plug valves don’t have as many types as ball valves. Most plug valves are full bore, especially rectangular port valves. Round port and diamond port valves can have reduced bores as well but they can only be used in low-pressure applications.

Source: https://hardhatengineer.com

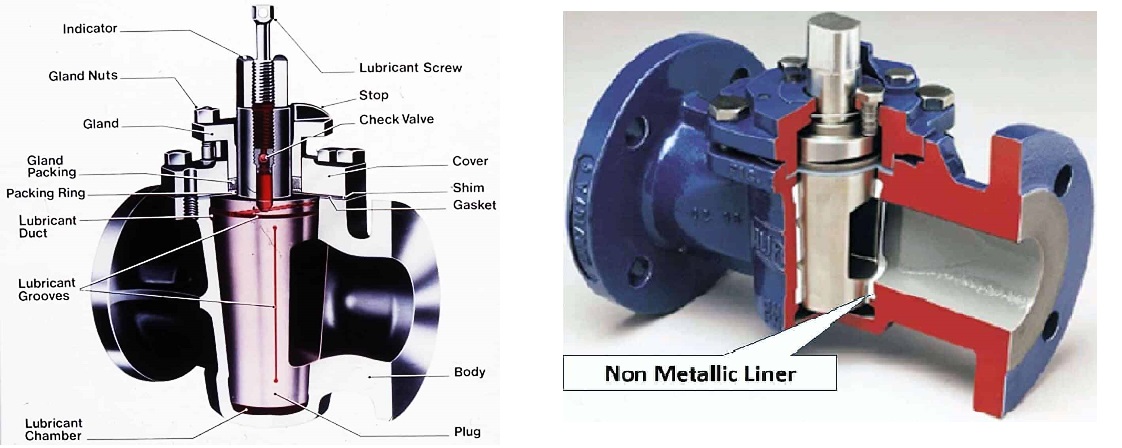

There are mainly two types of plug valves, lubricated plug valves and non-lubricated plug valves. Lubricated plug valves are usually made of metal and they feature a lubricant chamber that constantly lubricates the plug of the valve. The lubricated plug is easier to move, has low friction, and is corrosion-resistant. Lubricated plug valves can be used in larger applications and handle high-temperature services.

Source: https://hardhatengineer.com

Non-lubricated plug valves feature a non-metallic elastomeric sleeve that is installed between the plug and the body of the valve. This sleeve reduces any friction between the plug and the body. However, the non-metallic seat means this type of valve cannot be used in high-temperature services.

Longevity

Generally, ball valves have a greater lifespan than plug valves. A plug valve has to deal with greater torque and more of its surface area comes in contact with the medium. This means the valve has more wear and tear and is more prone to corrosion. Ball valves have special mechanisms in place that prevents the medium from being in constant contact with the disc. Though it has more moving parts, the low torque means less wear and tear.

Control Capability

Ball valves can be controlled using manual, electric, hydraulic, pneumatic, and many other kinds of actuators. They are easy to open and close and require very little force even when operating under high-pressure conditions. Plug valves can be operated using manual and electric actuators. They can be operated through pneumatic actuators as well but they are very expensive to install. Plug valves can be difficult to open and close in high-pressure operations due to the high amount of torque. This is the reason why plug valves are usually not used for larger applications.

Customization

Both ball and plug valves can be customized to suit specific applications. However, ball valves have a greater margin for customization than plug valves, like customing air operated ball valve. The sheer variety of ball valves available in the market means you have a lot of features to choose from. Ball valves can be unidirectional, bidirectional, or multidirectional. They can have one, two, or three-piece body as well as multiple ports. You can find top-entry, end-entry, side-entry, and split-body ball valves. Ball valves can also be customized to have double block and bleed capabilities.

Source: https://hardhatengineer.com https://hardhatengineer.com

Plug valves can also be customized but in a limited capacity. This is because they feature a simple structure with little room for improvement. You can find multi-port plug valves in the market that start from 2 ports and go all the way up to 5 ports. Though care must be taken while operating multiport valves as they might not provide a very tight shut-off. All other kinds of customizations on a plug valve like installing electric or pneumatic actuators or adding anti-friction components are very expensive.

What are the Applications of Ball and Plug Valves?

Both ball and plug valves are used extensively in different piping applications. Plug valves are used to provide bubble tight shut-off in fluid services like air, gas, vapor, hydrocarbon, and more. Plug valves are a popular valve to use when dealing with slurries, mud, and sewage applications as they have a larger surface area and allow unrestricted flow of the medium. Fortified plug valves are used to provide tight seals when dealing with corrosive or hard mediums. There simple operating structure and anti-corrosion qualities make them the most reliable shutoff option in critical applications.

Ball valves are used in many different industries. Their versatility makes them a popular choice for turbine skids, gas feed lines, compressor skids, crude oil plants, generator skids, polymer plants, separator skids, LNG plants, field gas plants, industrial gas processing plants, tank farms, oil refinery feedstock lines, hydrocarbon processing, and automated process applications. High-pressure ball valves are used in subsea, wastewater treatment, underground, and cryogenic services. Stainless steel and carbon steel ball valves are used in cooling water, feedwater, petroleum refining, desalination, and brewing.

Conclusion

Ball and plug valves are control valves that are used to provide bubble tight seals in many different applications. They are the common types of valves in ship, energy, and other industrial applications. While plug valves have better sealing abilities they are difficult to operate and are expensive and heavy for large-scale use. Ball valves may have less impressive sealing abilities but they are easy to operate and can be easily scaled up for larger applications. Furthermore, their sealing capabilities can be enhanced with added technology and mechanisms. You can find a variety of ball and plug valves in our catalogs. Looking for advice on your valve needs, reach out to us to get expert opinions on your applications.

2 Comments

Useful information about plug and ball valves, give information about design of valves.also give information about other valves like gate and globe, safety relief valves, breather valves, needle valves etc

Thanks for your comment Nikunj! Feel free to check out other blogs to read more content related to valves! Also let us know if you have any questions!